Different OptiSORT Feeding configurations

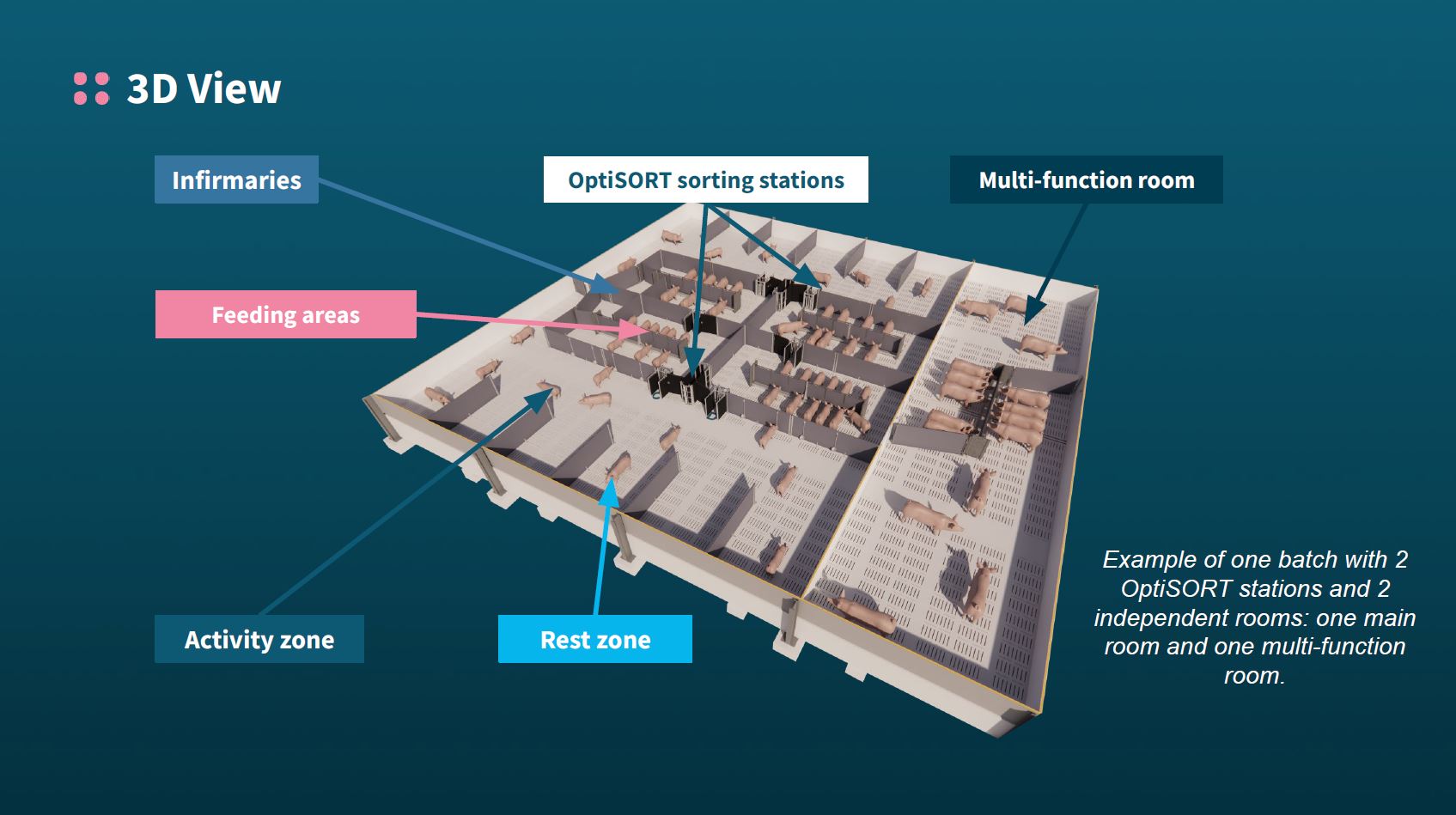

1/ Managing pigs in large groups

Large group farming involves raising a large number of pigs (100 to 450 maximum) in the same space in order to optimize the building, respect their natural behavior and promote their well-being.

This approach encourages the expression of gregarious behaviors, limits conflict and stress. The animals benefit from greater freedom of movement and evolve in an environment adapted to their natural rhythm.

An infirmary area is integrated directly into the room to quickly isolate weakened pigs, while still allowing them visual and olfactory contact with their companions. Once recovered, they can be reintegrated into the group without conflict.

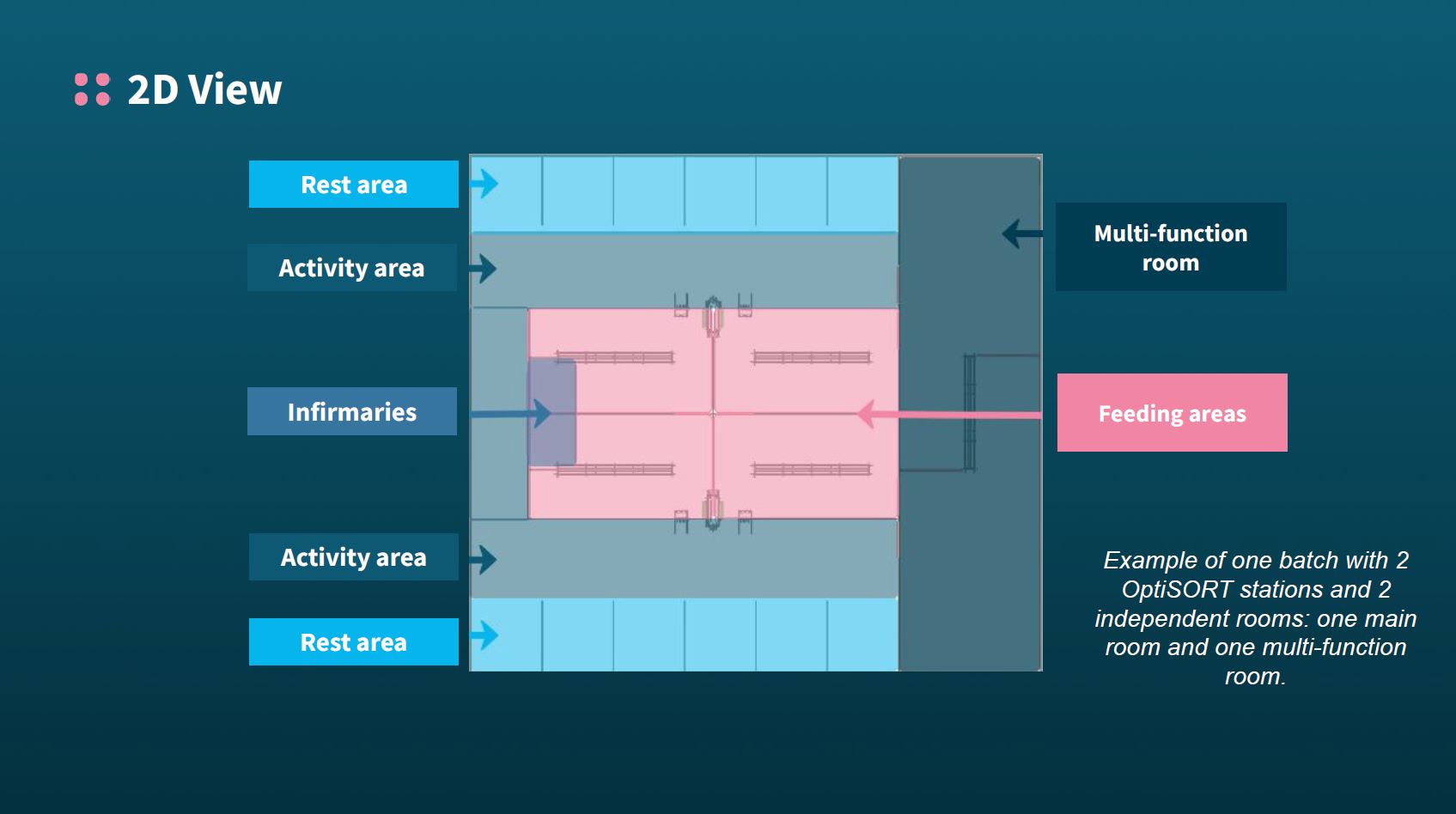

2/Intelligent organization of spaces

The room is designed into clearly differentiated zones, each with a specific function: feeding, activity and rest. This intelligent organization improves animal comfort and simplifies the farmer’s work.

A multi-functional room completes the complex: it allows the finishing of the fattening of the lightest pigs, the storage of animals before their departure to the slaughterhouse and the provision of more space for pigs from the second third of fattening.

This modularity allows for the optimization of building space utilization while improving animal welfare.

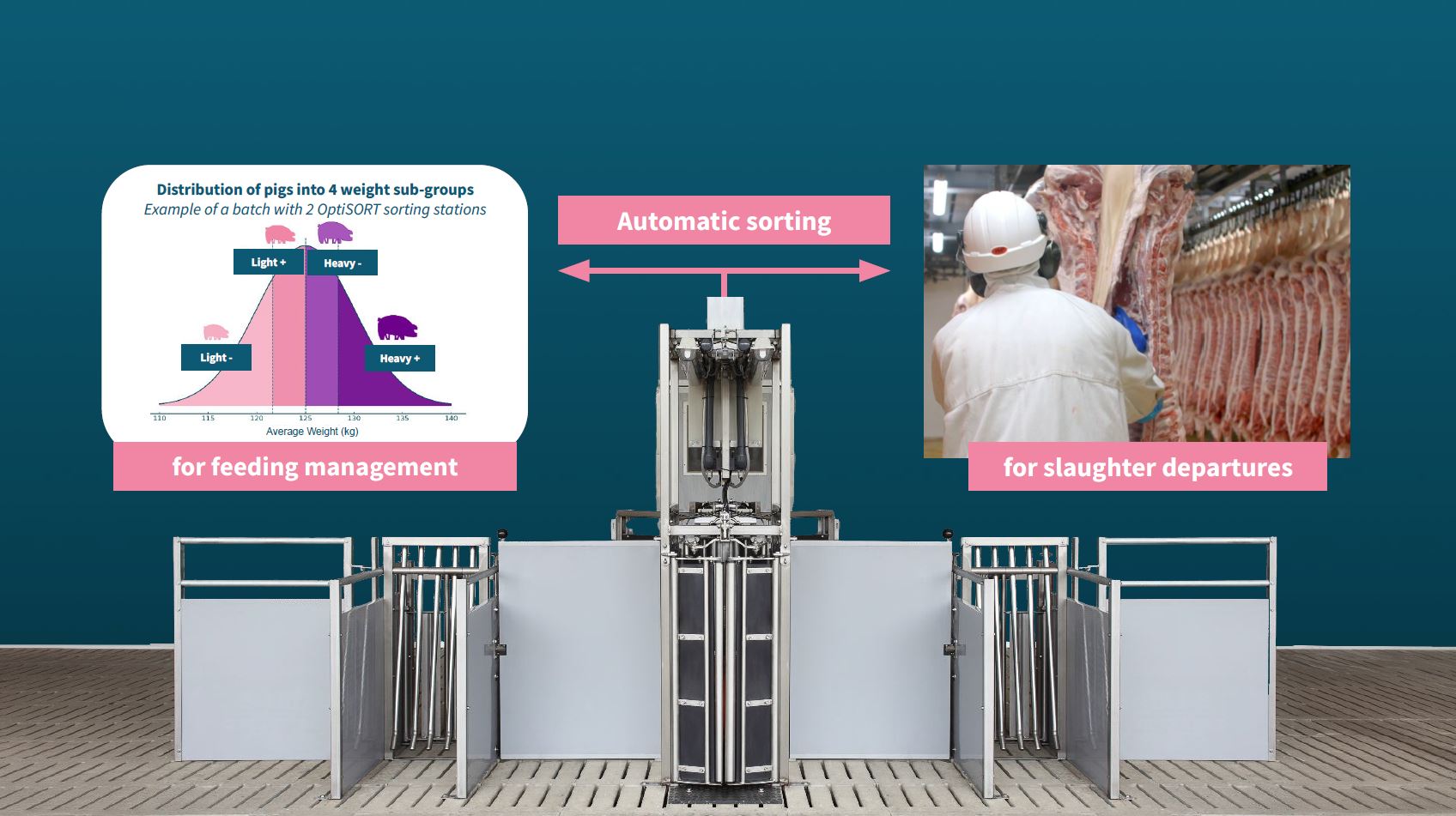

3/ OptiSORT optical sorting station

At the heart of the system, the OptiSORT station provides automated optical weighing and sorts the pigs without any human intervention. It automatically weighs and directs the animals to adjust their feed according to their weight and to select them at the optimal time for their departure to the slaughterhouse.

Thanks to this dynamic sorting, homogeneous subgroups are formed and each benefits from a specific feeding area, guaranteeing a ration adjusted to their real needs.

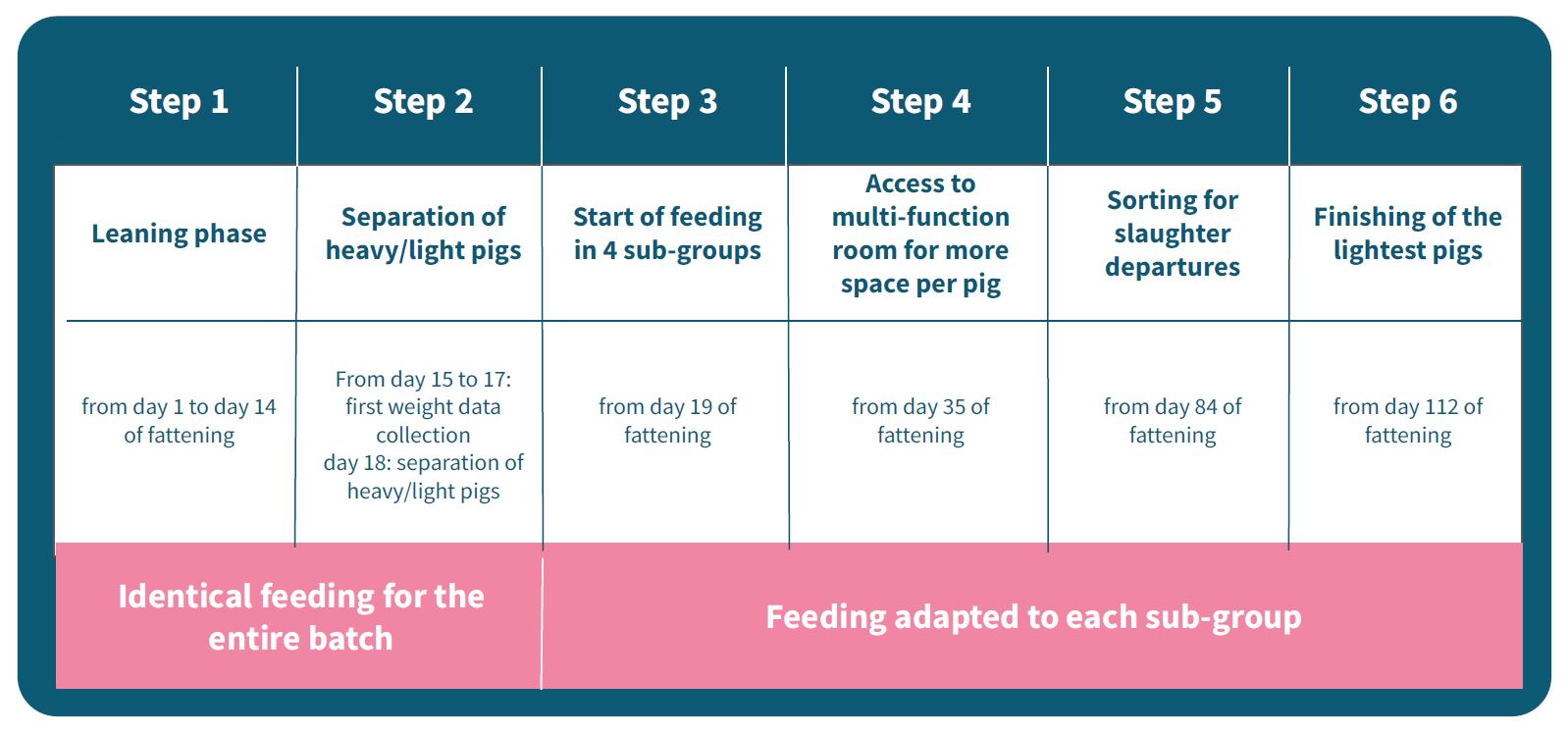

4/ Sequenced driving in 6 steps

This 6-step management system allows for continuous adaptation of animal management and feeding. Upon arrival, the pigs learn to use the station, then are progressively divided into homogeneous subgroups according to their weight.

From the 19th day of fattening, feeding begins in subgroups, allowing precise monitoring of growth and better feed efficiency.

At the end of the batch, the multi-functional room facilitates the grouping of the last pigs to be fattened and optimizes the use of the building.

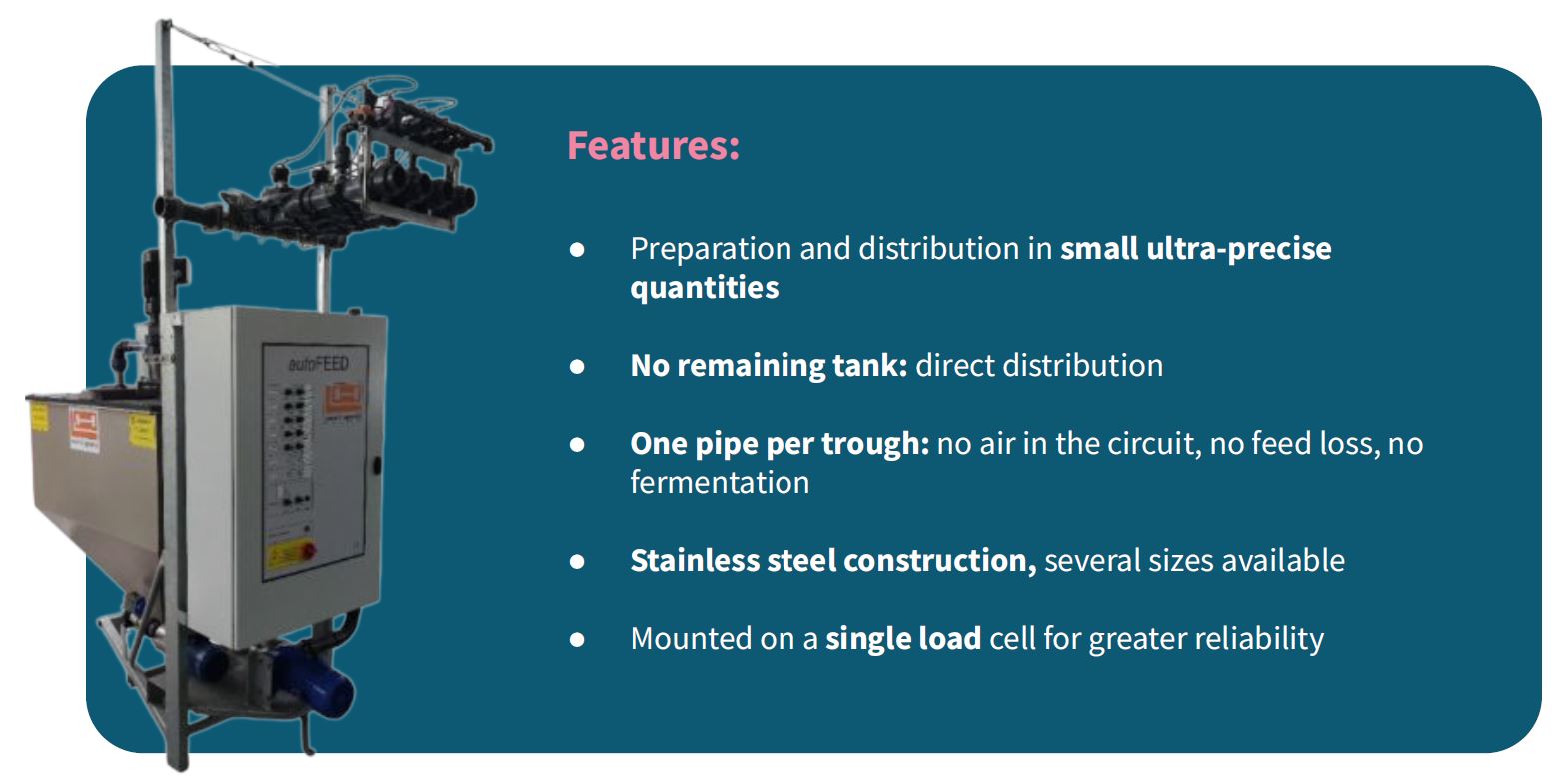

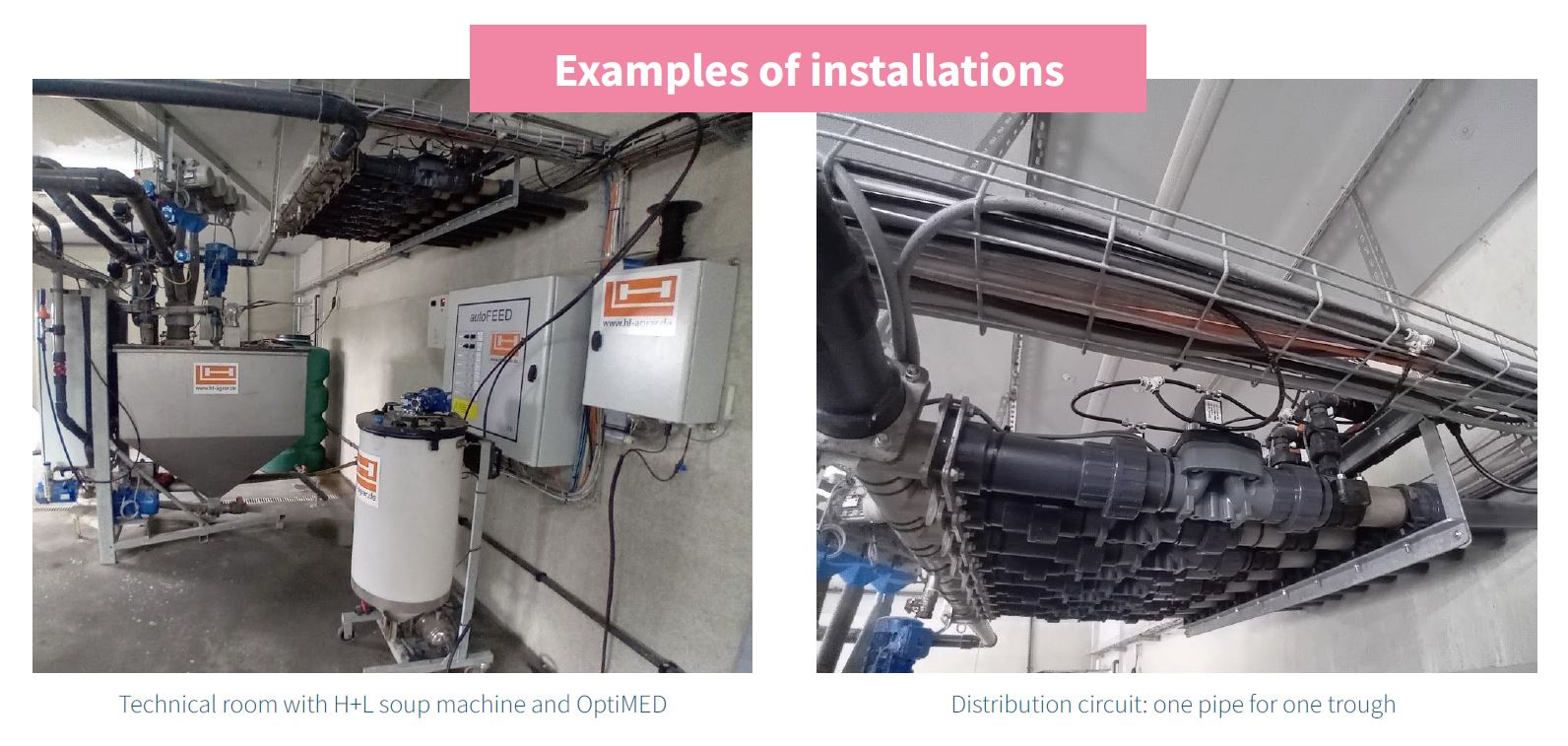

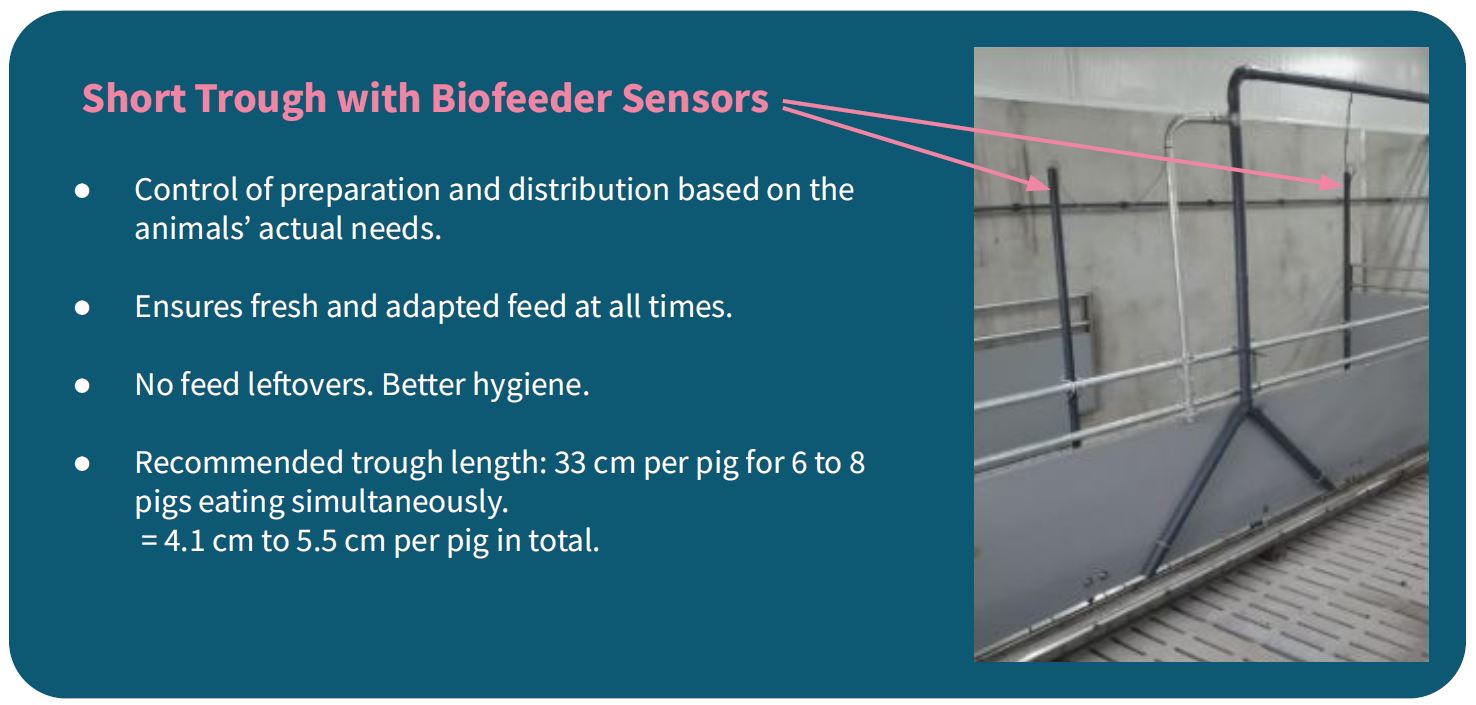

5/ High-precision H+L soup machine

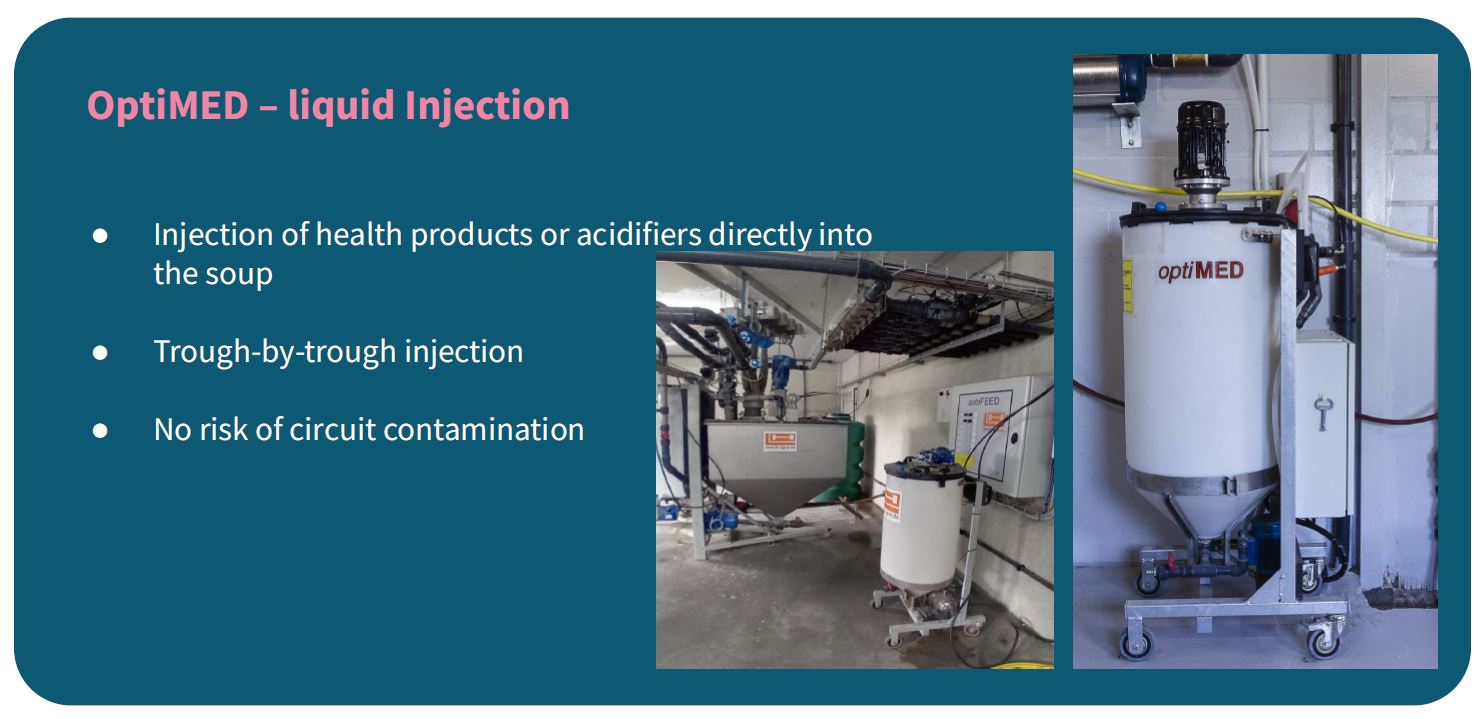

Designed for small batches of 40 kg or more, this machine operates on the principle of one circuit = one trough. It prepares highly precise rations, tailored to the needs of subgroups, and communicates directly with the OptiSORT station.

The result: an automatically controlled feeding system, with no losses or leftovers, guaranteeing a high level of hygiene and optimized feed management.

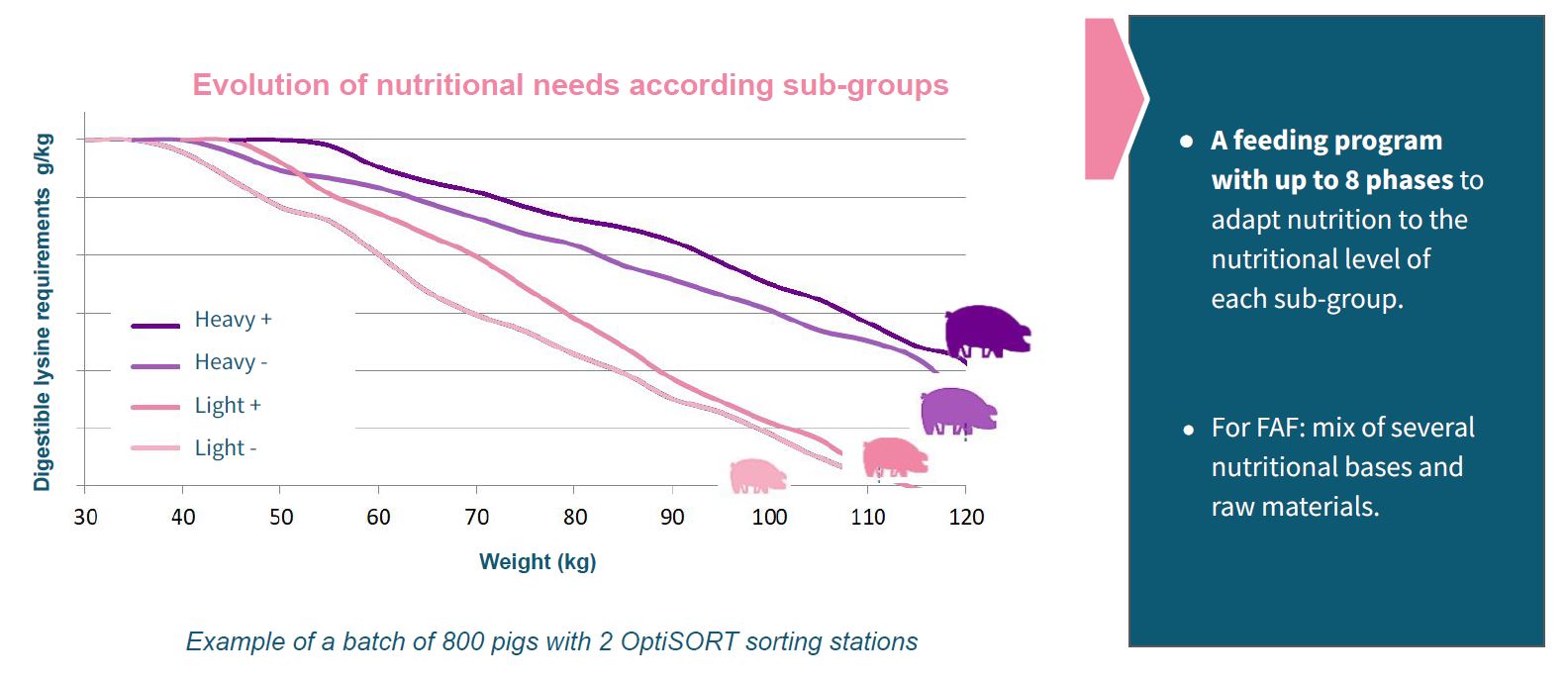

6/ The specific diet program of Cooperl Nutrition

This program combines up to 8 food phases, reconstituted from several nutritional bases (standard foods + raw materials in the case of FAF).

Connected to OptiSORT sorting, it allows for automatic adjustment of feeding transitions based on the actual weight and growth of animal subgroups.